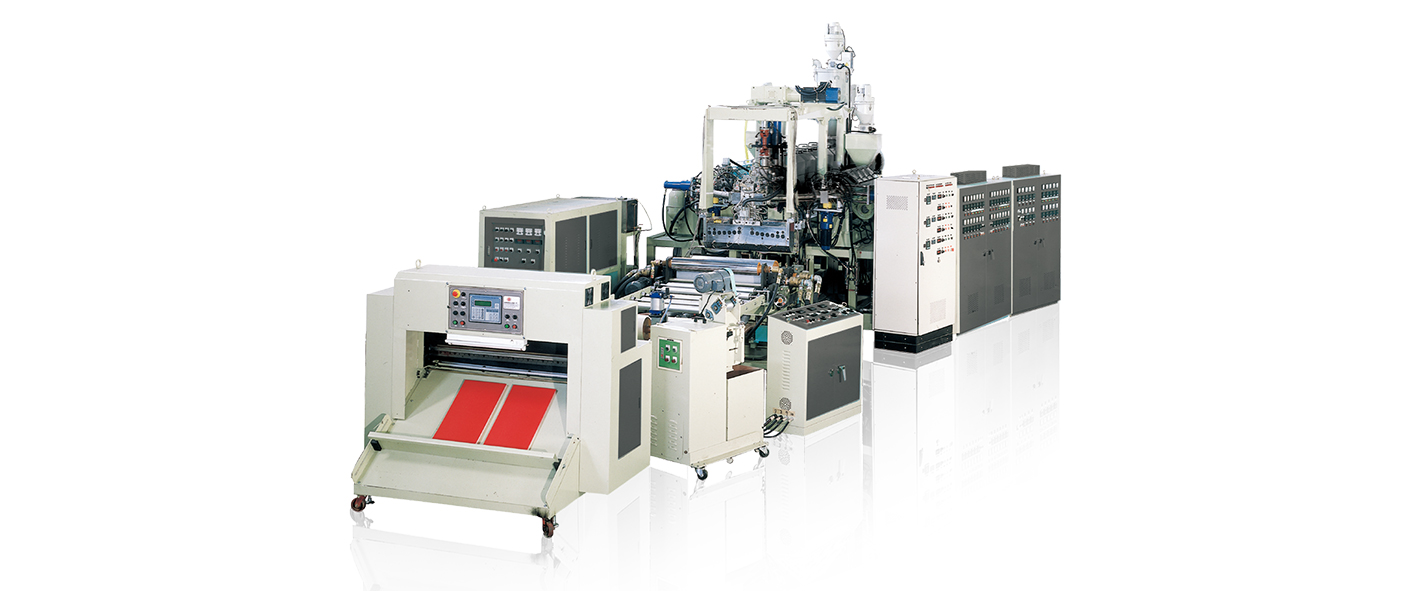

- Screw is of special mixing function and hi-plasticizing capacity design, it incorporates with static mixer and gear pump to ensure melting of resins, foaming proportion stable, homogeneous color increase on extruding output.

- 3 shafts of screws are equipped the twin shaft screen changer to increase convenience and production.

- 3 shafts of screws are equipped the gear pump to control output, the pressure and time inside the screw to stabilize the foaming proportion and accurate thickness.

- Die head is made of special double throttling design to enable adjustment for sheet thickness to be more accurate. The die lip uses heating kerosene cooling system to make material more stable and easy to operate.

- Temperature control uses SCR system, tolerance of temperature is ± 1, this may precisely control plasticizing processes, sheet thickness, flatness and neatness.

- Embossing shaping stand can move up and down, forward and backward freely. During operation, this will provide convenience and upgrade product quality.

- Sheet thickness control uses screw adjustment and hydraulic pressing roller two-way adjustment, this may control the sheet thickness precisely. Additional increased outer cooling system makes sheet lines beautiful and neat.

- Embossing roller of diameter and two-loop cooling system incorporates with microcomputer temperature controller will precisely control temperature of embossing roller so as to make sheet be flat and neat and to keep thickness homogeneous.

- Slicing unit uses microcomputer control to enable sheet length and quantify to be accurate.

- Electric control box: it completely uses high class and qualified accessories and it is of save space design, operation for that is simple and convenient.

- Gear pump adopts servo motor to increase operation convenience and stability.

Multi-Layer PP Foam Sheet Making Machine

MGB-PPF-1100 3S

Features

Gallery

Specifications

swipe your finger

|

Model |

MGB-PPF-1100 3S |

| Layers distribution | ABC, ABC |

| Non-foam type | 0.3 - 2 mm |

| Foam type | 1.2 - 3 mm |

| Width | 950 mm |

| Output | About 150 - 250 kg/hr (Depend on the thickness) |

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. |