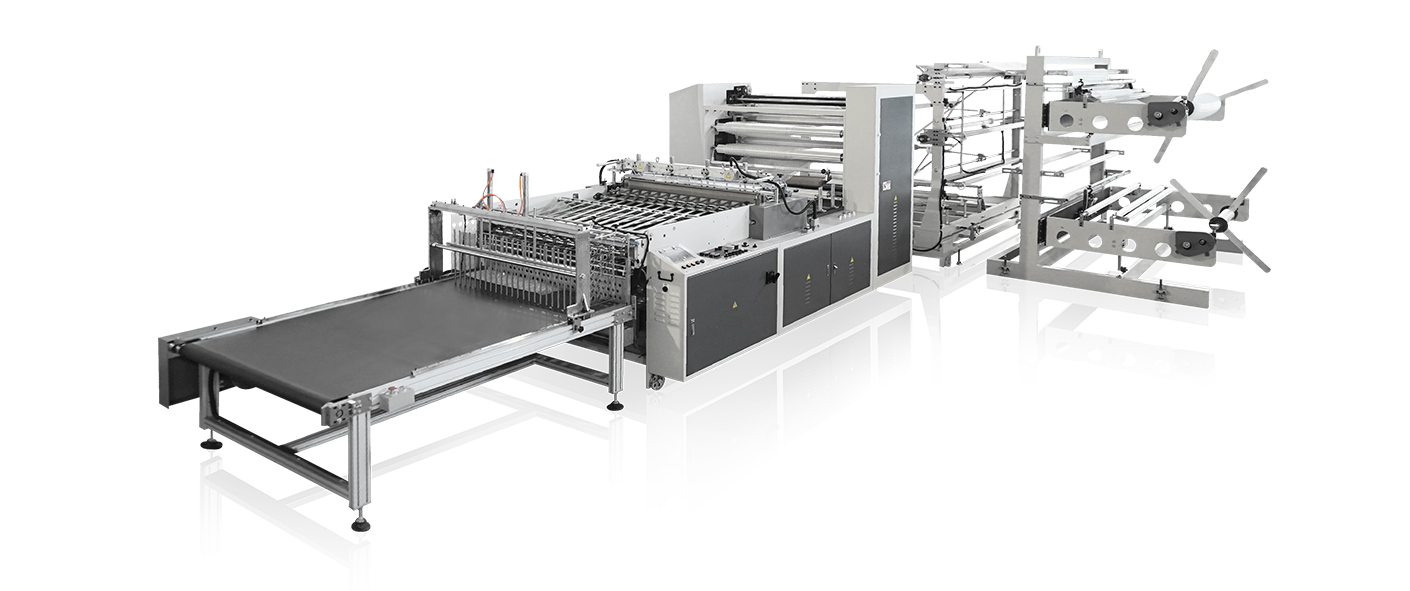

Twin Lines Air Bubble Bag Making Machine

MGA-25-SERIES

Features

The Ming Jilee Twin Lines Air Bubble Pouch Machine is designed for efficient production of air bubble bags. This machine is equipped with an edge position controller to precisely control the flap length, ensuring consistent dimensions for each pouch. Additionally, it features a high-quality wire impulse sealing system, allowing temperature adjustments for various production applications and precise cutting of EPE foam. The twin lines design includes two dancing roll stations, enabling effective control of the air bubble film tension for stable production. To enhance operational convenience, the machine incorporates a non-stop collecting conveyor, making it easy for operators to collect the finished bags. For high-volume production of smaller bags, the twin lines design is an ideal choice.

Specifications

swipe your finger

| Model | MGA-25-800A | MGA-25-1000A | MGA-25-1200A | MGA-25-1600A |

| Thickness (mm) |

.Air Bubble Diameter : 5 - 15 .EPE Foam : 0.5 - 2.5 |

|||

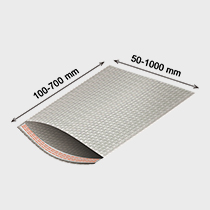

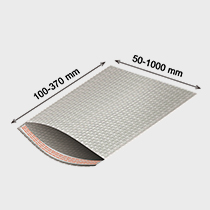

| Bag Size Range Single Line (L x W mm) | 100 - 750 x 100 - 1,000 | 100 - 950 x 100 - 1,000 | 100 - 1,150 x 100 - 1,000 | 100 - 1,500 x 100 - 1,000 |

| Bag Size Range Twin Line (L x W mm) | 100 - 350 x 100 - 1,000 | 100 - 450 x 100 - 1,000 | 100 - 500 x 100 - 1,000 | 100 - 600 x 100 - 1,000 |

| Output (cycle/min) | 20 - 100 | |||

| Dimension of Machine (L x W x H mm) | 8,800 x 4,850 x 2,000 | 8,800 x 5,380 x 2,000 | 8,800 x 4,400 x 2,000 | 8,800 x 4,950 x 2,000 |

| Power Consumption (kw) | 10 | 12 | 15 | 18 |

| Optional equipment | A/B pocket heating sealing device ( on same bag ) | |||

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. | |||