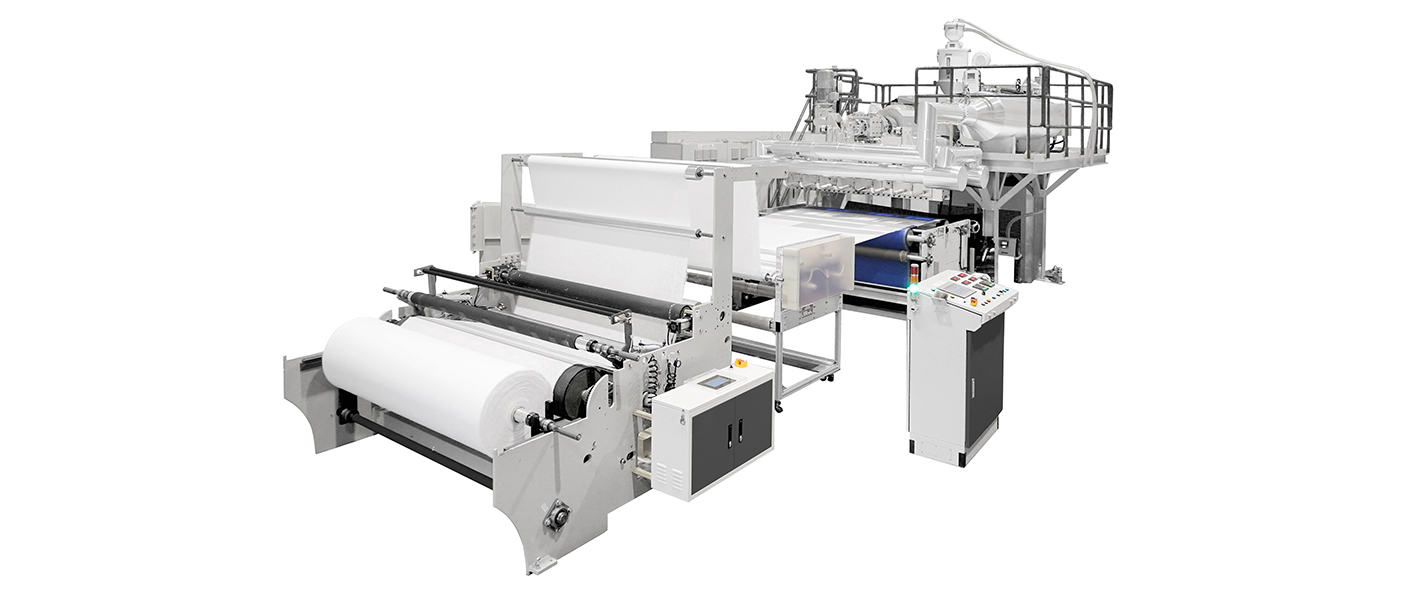

The PP Melt Blown Fabric Extrusion Line is equipped

- High efficient AC motor with direct driven gear box motor.

- Huge hot air tank for collecting the enough hot air to produce the high filtration melt blown fabric.

- USA Made Electrostatic Charging System for high filtration melt blown fabric.

- The touch panel to control the linear speed, temp of extruder and air frequency.

- Friction type winder with in-line slitting device.

Machine Performance

PP Melt Blown Fabric Extrusion Line designs for producing High filtration efficiency melt blown fabric.

- The linear speed of 25 GSM is 25 – 30 meter/min.

- the output is 1500 – 2000 kg/day.

- BFE (Bacterial Filtration Efficiency): 95% up with 3 layers medical mask.

- PFE (Particle Filtration Efficiency): 90 % up by 1 layer 25 GSM, 0.3 um partical with 32 liter/min flow.