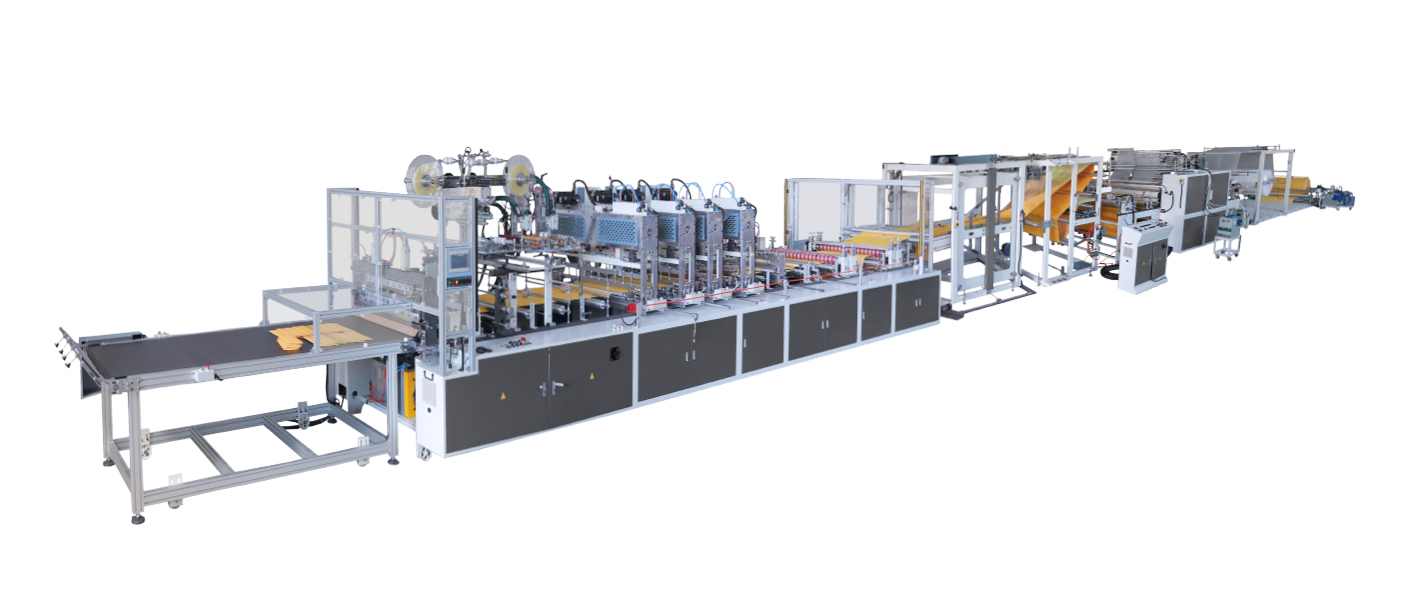

MGA-47E-900LAMF, Kraft Paper / PE Poly Bubble Mailer Making Machine is best design to produce Kraft paper / Courier PE Bubble Mailer. You just need to prepare separate material from Kraft Paper, Co-extruded LDPE film and Air Bubble Film, then you will get the perfect PE Courier & Kraft Paper Bubble Mailer.

- Air Bubble quick change: Due to the shorter length of air bubble, we design the quick change device to reach non-stop production for saving the waste because of the changing material.

- Best Lamination quality: Kraft Paper / PE Poly Bubble Mailer Making Machine is installed European brand lamination system to do in-line lamination for Kraft paper with air bubble film or LDPE with air bubble film. With special design, we won’t break the air bubble after laminating processing.

- Strongest edge Sealing Seam: The transversal sealing seam of Kraft Paper / PE Poly Bubble Mailer Making Machine is controlled by motor, with mechanical driven system, it makes sure the operator to get the higher pressure and best sealing quality.

- In-line hot melt glue system: MING JILEE only choose the global and premium suppliers to install the hot melt system on MING JILEE Kraft Paper / PE Poly Bubble Mailer Making Machine. it gets perfect glue control to reach intermittence glue or continuous glue function.

-

Synchronizing length control: Kraft Paper / PE Poly Bubble Mailer Making Machine is equipped many servo motors to Synchronize the length supply. With special belt system, we can feed the precise length to cut the exact setting size without any slippery of material.

-

Multi-function auto conveyor: with serval quantity setting, to get special stacking as operator’s favorite way. It helps operators to take already counter mailer for last packing purpose.

_pic_spic.jpg)